rebar

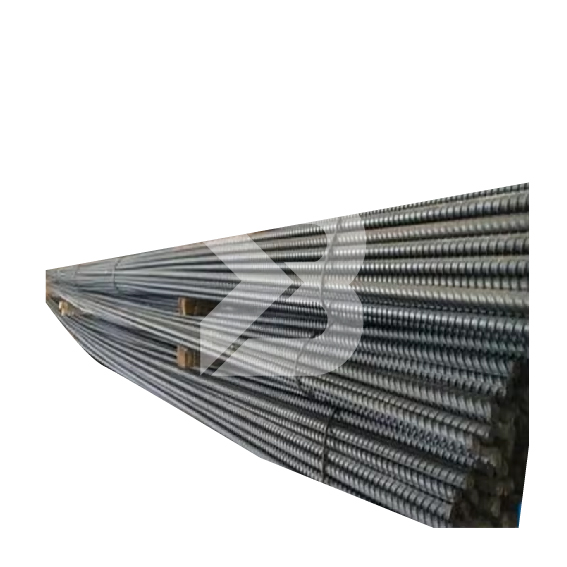

Product Introduction – Rebar

1. Product Overview

Product Name: Rebar (Reinforcing Steel Bar)

Description:

Rebar is a high-strength steel bar widely used in reinforced concrete structures. It provides tensile strength to concrete, significantly improving structural load-bearing capacity and reliability. Manufactured from carbon steel or low-alloy steel, rebar features excellent toughness, durability, and bonding performance with concrete.

⸻

2. Core Keywords

Rebar, reinforcing steel, concrete reinforcement, building materials, carbon steel rebar, low-alloy rebar, structural reinforcement, construction steel bar, BLUBRO rebar, sustainable construction materials.

⸻

3. Specifications

Item Details

Material Carbon steel / Low-alloy steel (customizable)

Diameter (Size) Common sizes: 10 mm, 12 mm, 16 mm, 20 mm, 25 mm, or Imperial sizes #3–#11

Surface Type Ribbed / Deformed

Strength Grade Grade 40 (280 MPa), Grade 60 (420 MPa), Grade 75 (520 MPa), Grade 80

Unit Weight Example: #4 (12.7 mm) ≈ 0.668 lb/ft (≈0.996 kg/m)

Length Standard lengths 6m, 9m, 12m or customized

Processing Hot-rolled, cutting, bending, customized fabrication available

⸻

4. Testing & Standards

• Chemical Composition Analysis: Ensure carbon (C), silicon (Si), manganese (Mn) contents meet design requirements.

• Mechanical Properties Testing: Yield strength, tensile strength, elongation rate according to international standards.

• Welding & Bending Test: For projects requiring welded or bent rebars (per ASTM A706).

• Standards Compliance:

• ASTM (USA): A615, A706, etc.

• BS (UK): BS 4449:97 (high ductility rebar).

• CSA (Canada), GB (China) and other regional standards.

• Third-party Inspection: SGS, TÜV, CNAS certificates available upon request.

⸻

5. Applications & Benefits

Applications:

• Civil & Industrial Buildings: slabs, beams, columns, staircases, foundations.

• Infrastructure: bridges, highways, subways, tunnels.

• Precast and prefabricated concrete components.

Advantages:

• High strength & durability for long-term safety.

• Ribbed surface improves bond between rebar and concrete.

• Flexible specifications to meet different project requirements.

• Sustainable material option with recycled steel.

• Full processing support: cutting, bending, prefabrication, and on-demand supply.

⸻

6. Page Optimization Suggestions

1. Replace the placeholder “CONTACT NOW download to pdf” with:

“Download detailed product specifications (PDF) or contact us for full material composition, mechanical properties, sizes, and pricing information.”

2. Insert the specifications table for better readability.

3. Add application images (construction sites, bridges, high-rise buildings).

4. Highlight quality testing certifications (ASTM, SGS, TÜV, BS, GB).

5. Use the above keywords in product description and meta tags to improve SEO.

6. Add clear Call-to-Action (CTA) buttons: “Download Datasheet” / “Get a Quote Now.”

⸻

7. Sample Copy for Website

Product Name: BLUBRO Rebar (Reinforcing Steel Bar)

Description:

BLUBRO rebar is manufactured from high-quality carbon steel or low-alloy steel, processed through hot rolling with ribbed surface design. It is widely used for strengthening concrete structures and providing long-lasting reinforcement for construction projects.

Specifications:

• Material: Carbon steel / Low-alloy steel

• Diameter: 10 mm, 12 mm, 16 mm, 20 mm, 25 mm (Imperial #3–#11 available)

• Grade: Grade 40 / 60 / 75 / 80

• Unit Weight: Example #4 (12.7 mm) ≈ 0.996 kg/m

• Length: Standard 6m / 9m / 12m or customized

• Surface: Ribbed / Deformed

• Processing: Cutting, bending, customized fabrication

Testing & Standards:

Compliant with ASTM A706 / A615, BS 4449:97, GB, and other standards. SGS, TÜV inspection reports available.

Applications & Benefits:

• High strength, reliable performance

• Ribbed design for superior concrete bonding

• Flexible processing services (cutting, bending, prefabrication)

• Environmentally friendly with recycled steel option

• Widely used in civil, industrial, and infrastructure projects

Download Datasheet: Click to download detailed PDF specifications and test reports.

Contact Us:

+86-13202436999

maxwell@blubro.com

Product Introduction – Rebar

1. Product Overview

Product Name: Rebar (Reinforcing Steel Bar)

Description:

Rebar is a high-strength steel bar widely used in reinforced concrete structures. It provides tensile strength to concrete, significantly improving structural load-bearing capacity and reliability. Manufactured from carbon steel or low-alloy steel, rebar features excellent toughness, durability, and bonding performance with concrete.

⸻

2. Core Keywords

Rebar, reinforcing steel, concrete reinforcement, building materials, carbon steel rebar, low-alloy rebar, structural reinforcement, construction steel bar, BLUBRO rebar, sustainable construction materials.

⸻

3. Specifications

Item Details

Material Carbon steel / Low-alloy steel (customizable)

Diameter (Size) Common sizes: 10 mm, 12 mm, 16 mm, 20 mm, 25 mm, or Imperial sizes #3–#11

Surface Type Ribbed / Deformed

Strength Grade Grade 40 (280 MPa), Grade 60 (420 MPa), Grade 75 (520 MPa), Grade 80

Unit Weight Example: #4 (12.7 mm) ≈ 0.668 lb/ft (≈0.996 kg/m)

Length Standard lengths 6m, 9m, 12m or customized

Processing Hot-rolled, cutting, bending, customized fabrication available

⸻

4. Testing & Standards

• Chemical Composition Analysis: Ensure carbon (C), silicon (Si), manganese (Mn) contents meet design requirements.

• Mechanical Properties Testing: Yield strength, tensile strength, elongation rate according to international standards.

• Welding & Bending Test: For projects requiring welded or bent rebars (per ASTM A706).

• Standards Compliance:

• ASTM (USA): A615, A706, etc.

• BS (UK): BS 4449:97 (high ductility rebar).

• CSA (Canada), GB (China) and other regional standards.

• Third-party Inspection: SGS, TÜV, CNAS certificates available upon request.

⸻

5. Applications & Benefits

Applications:

• Civil & Industrial Buildings: slabs, beams, columns, staircases, foundations.

• Infrastructure: bridges, highways, subways, tunnels.

• Precast and prefabricated concrete components.

Advantages:

• High strength & durability for long-term safety.

• Ribbed surface improves bond between rebar and concrete.

• Flexible specifications to meet different project requirements.

• Sustainable material option with recycled steel.

• Full processing support: cutting, bending, prefabrication, and on-demand supply.

⸻

6. Page Optimization Suggestions

1. Replace the placeholder “CONTACT NOW download to pdf” with:

“Download detailed product specifications (PDF) or contact us for full material composition, mechanical properties, sizes, and pricing information.”

2. Insert the specifications table for better readability.

3. Add application images (construction sites, bridges, high-rise buildings).

4. Highlight quality testing certifications (ASTM, SGS, TÜV, BS, GB).

5. Use the above keywords in product description and meta tags to improve SEO.

6. Add clear Call-to-Action (CTA) buttons: “Download Datasheet” / “Get a Quote Now.”

⸻

7. Sample Copy for Website

Product Name: BLUBRO Rebar (Reinforcing Steel Bar)

Description:

BLUBRO rebar is manufactured from high-quality carbon steel or low-alloy steel, processed through hot rolling with ribbed surface design. It is widely used for strengthening concrete structures and providing long-lasting reinforcement for construction projects.

Specifications:

• Material: Carbon steel / Low-alloy steel

• Diameter: 10 mm, 12 mm, 16 mm, 20 mm, 25 mm (Imperial #3–#11 available)

• Grade: Grade 40 / 60 / 75 / 80

• Unit Weight: Example #4 (12.7 mm) ≈ 0.996 kg/m

• Length: Standard 6m / 9m / 12m or customized

• Surface: Ribbed / Deformed

• Processing: Cutting, bending, customized fabrication

Testing & Standards:

Compliant with ASTM A706 / A615, BS 4449:97, GB, and other standards. SGS, TÜV inspection reports available.

Applications & Benefits:

• High strength, reliable performance

• Ribbed design for superior concrete bonding

• Flexible processing services (cutting, bending, prefabrication)

• Environmentally friendly with recycled steel option

• Widely used in civil, industrial, and infrastructure projects

Download Datasheet: Click to download detailed PDF specifications and test reports.

Contact Us:

+86-13202436999

maxwell@blubro.com