2025.7.28 Steel platform case of blubro company

2025.7.28 Steel platform case of blubro company

Blubro Steel Platform Case Study (2025.7.28) - Professional Keywords & Product Specifications

Core Keyword Groups

"Custom Industrial Steel Platforms" "Heavy Steel Structure Solutions" "Blubro Premium Steel Applications" "Durable Platform Engineering" "Enterprise-level Steel Structure Cases"

Article Description

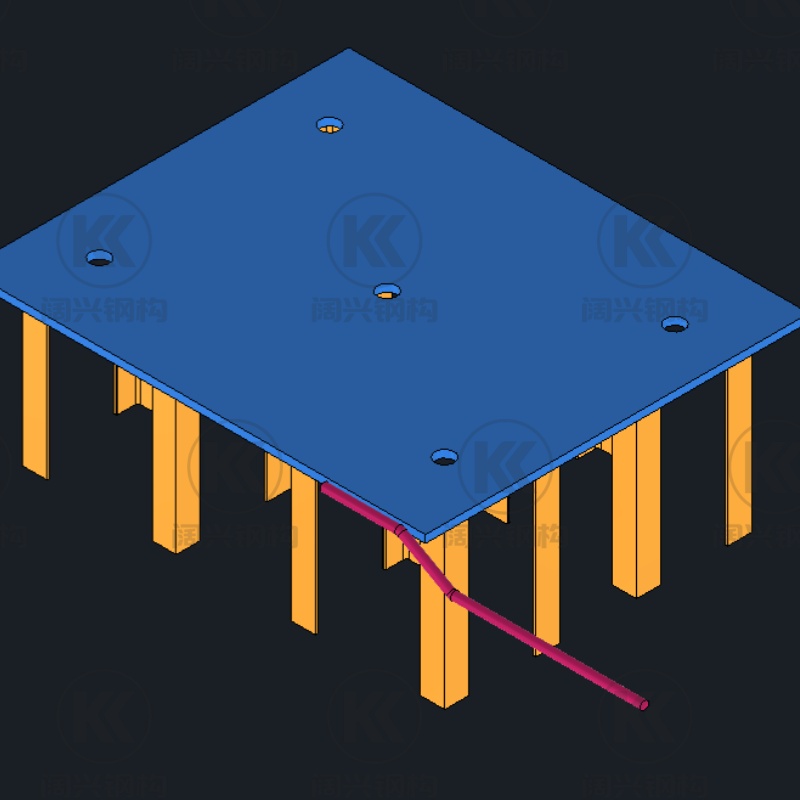

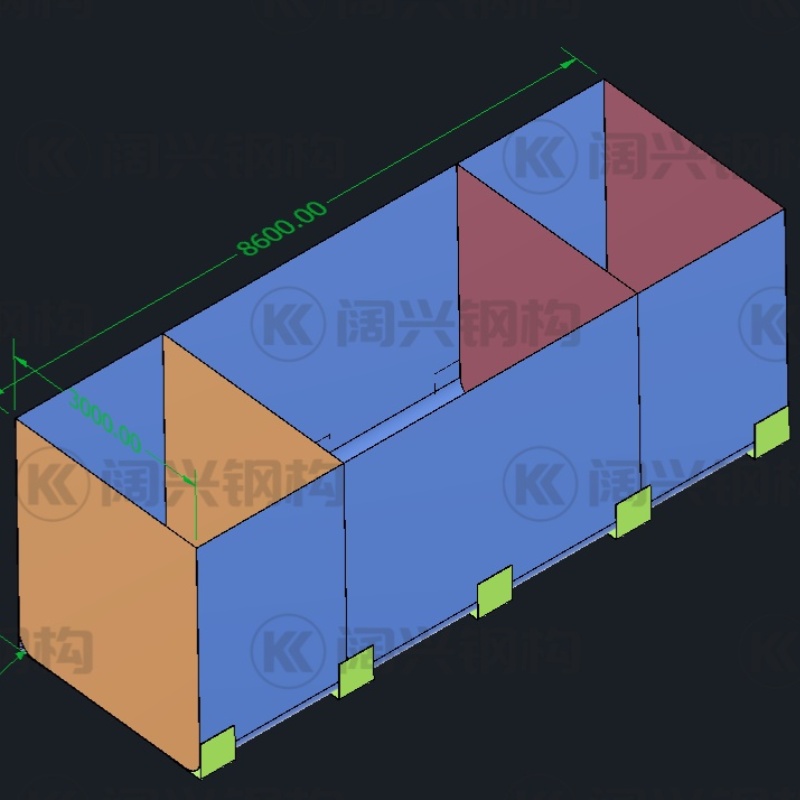

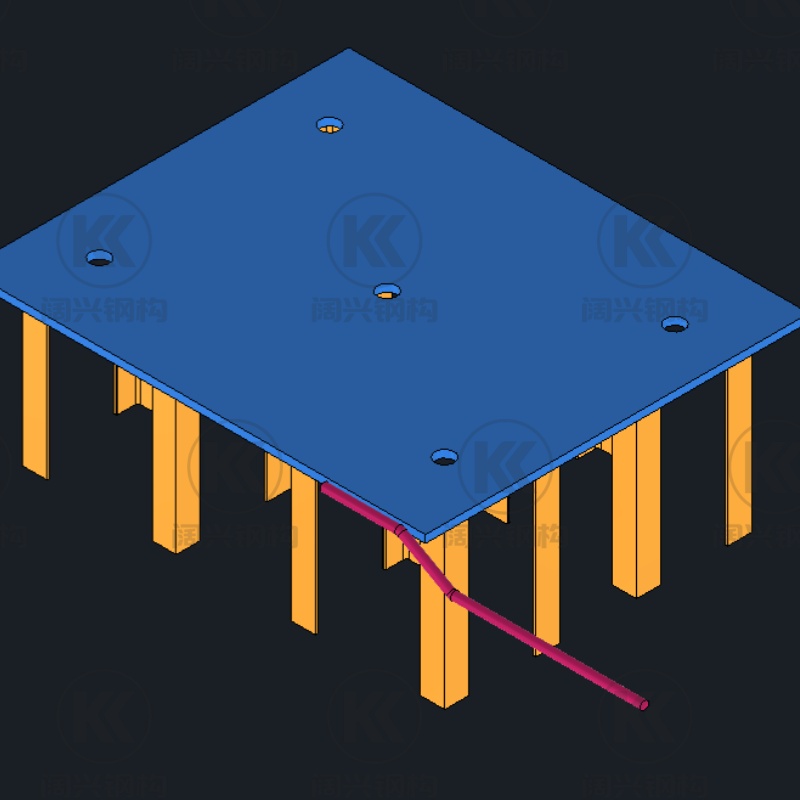

This showcases Blubro's flagship 2025 steel platform project case study, detailing an industrial platform constructed with ASTM A572 Grade 50 high-strength steel. Through automated welding processes and modular design, it achieves exceptional load-bearing capacity of 25 tons/m², demonstrating Blubro's technical leadership in heavy industrial steel structures.

Technical Specifications

Material Properties

Primary Material: Blubro Special Alloy Steel (Tensile Strength ≥450MPa)

Anti-corrosion Treatment: Hot-dip Galvanization (80μm) + Epoxy Coating

Fire Rating: BS 476 Class 1 Certified

Advanced Manufacturing

Laser Cutting Precision: ±0.5mm

Robotic Welding: SAW + GMAW

Modular Assembly System: Reduces onsite installation time by 40%

Engineering Parameters

Standard Span: 6-15m (Customizable)

Platform Thickness: 12-25mm Options

Anti-slip Design: Diamond Pattern Plate (Ra≥75μm)

Competitive Advantages

✓ Structural Performance

Dynamic Load Capacity Meets EN 1991-3 Standards

Seismic Design Complies with Zone 4 Requirements

✓ Cost Efficiency

Bulk Purchase Price: $380-650/m² (FOB Basis)

Service Life: 25+ Years (60% Lower Maintenance Cost)

✓ Customization Services

72-hour Design Proposal Delivery

BIM Model Support Available

Typical Applications

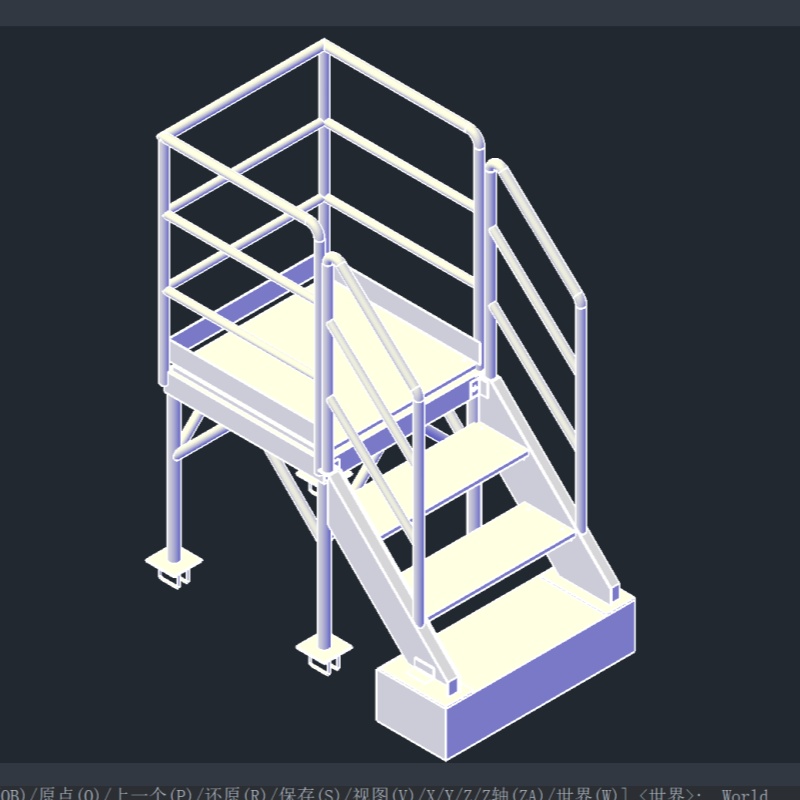

• Petrochemical Plant Maintenance Platforms

• Port Machinery Walkways

• Power Plant Equipment Layers

• Mine Conveyance Systems

(Note: Detailed case parameters available in Blubro's official engineering database)

Innovative Design and Technica

Innovative Design and Technica

Blubro.com: Engineering Excell

Blubro.com: Engineering Excell

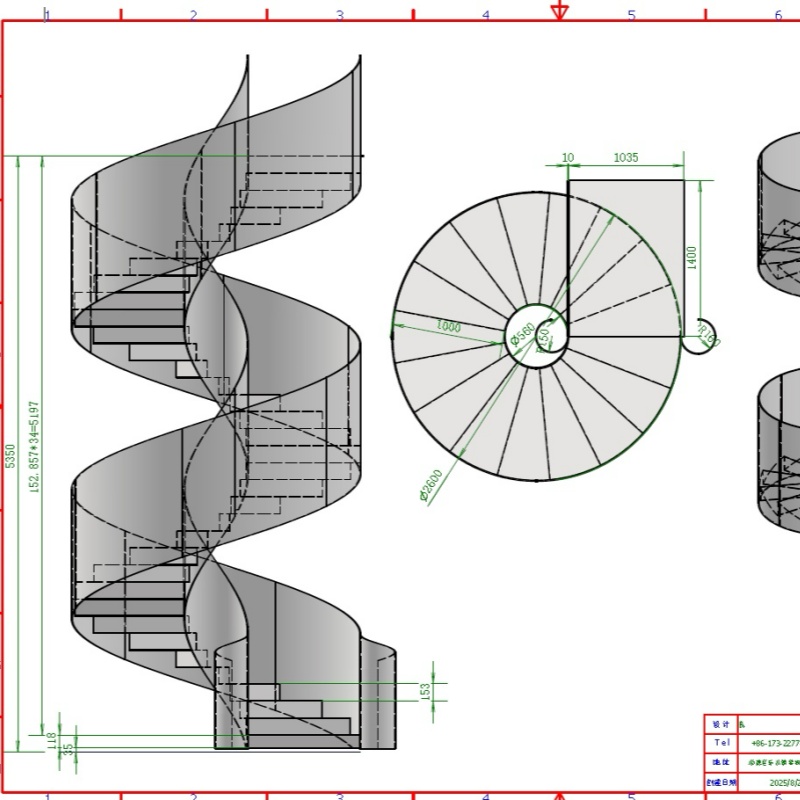

Case Study: Steel Staircase De

Case Study: Steel Staircase De

2025.7.28 Steel platform case

2025.7.28 Steel platform case